Rationalized safe packaging and clear markings reduce the operating costs of customers' warehouses and increase customers' tallying efficiency and delivery efficiency.

01

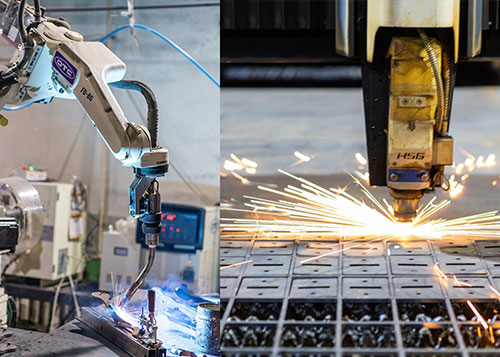

Fully automated raw material processing equipment and robot arm welding machines improve the stability of product quality, help customers win the market by quality, improve the user experience and increase customer sales.

02

Customized uprights and accessories, confirming design details in advance before actual production, all these help to solve the problem of mismatching components and help to increase customer satisfaction.

03

Modular production greatly improves the plasticity of customers' styles, increases customer sales, helps customers win market share, and reduces customers' inventory pressure.

04

Leave a Message