1.produce various kettlebells and cast iron plates;2.produce various steel plates.

Certifications Passed: SGS REACH CE SLCP FEM 7P QMS RoHS FREE

Casting:Gross production capacity is 50 tons/day Equipment: 1 casting line

01

Rough cast product processing:Production capacity is 40 tons/day

02

Semi-finished products:production capacity is 20 tons/day,2 powder coated lines

03

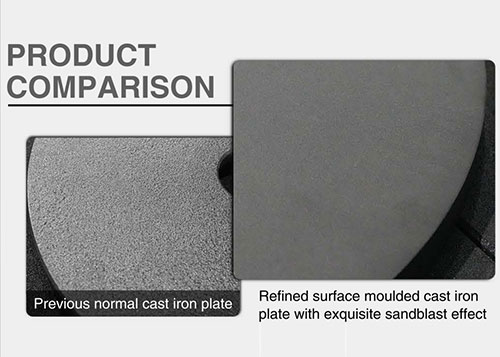

Advantages of Precoated sand:Delicate surface, Accurate weight, High efficiency, Energy saving and environmental protection

04

Leave a Message