The Evolution Of Barbell Bar Manufacturing From Traditional To Modern Techniques

Barbell bars are a vital piece of strength training equipment found in gyms worldwide. While the fundamental purpose of a sturdy, load-bearing bar remains unchanged, manufacturing technology has evolved considerably over time. This article explores key milestones in how barbell bars have been engineered and fabricated – from rudimentary beginnings to today's advanced, automated processes.

Early Simple Production Methods

The earliest known barbells date back to Ancient Greece, consisting of stone spheres or metal balls with a thin rod running through them. Bars were made from simple iron or steel stock by blacksmiths of the era using manual hammering, cutting, and welding techniques. These basic methods continued into the early 20th century.

Bars often had very basic finishes – raw steel or painted at most. Early barbell bars had fixed weights, with thinner central shafts that provided minimal load support. The crude manufacturing provided inadequate consistency in size, straightness, and structural integrity. Nevertheless, these bars formed the genesis of the modern barbell.

Mechanization Revolutionizes Manufacturing

With the rising popularity of weight lifting in the 1950s and 60s, demand increased for higher quality, commercial-grade barbells. Manufacturing processes became somewhat automated using lathes for smoothing and machining, drill presses to create hand grip cavities, and more advanced mechanical polishing equipment. However, human finishing work remained extensive.

This period saw the introduction of techniques still used today, including cold drawing to enhance structural strength by aligning the grain, seamless pipe construction for rounded barbell ends, and chrome plating finishes for durability and corrosion resistance. Standardized sizing and new bar types like Olympic also emerged to meet growing sport demand.

Contemporary Automated Precision Manufacturing

State-of-the-art barbell production today has comprehensive automation from raw material processing through final inspection. Key technologies driving modern manufacturing excellence include:

- Computer-controlled machines for high precision cutting, bending, milling, grooving, and other fabrication processes.

- Robotic arms that handle movement and finishing work like deburring and polishing.

- Programmable logic controllers to govern manufacturing equipment, optimizing output.

- Automated measuring systems that validate bar dimensions, straightness, tensile properties, and more to tight tolerances.

- Powder coating systems and industrial ovens for durable, consistent coatings.

- Laser etching equipment for logos and identifying markings on finished bars.

Today's factories also leverage CAD, simulation, and quality control software to continually refine processes. Multi-axis CNC machining centers perform complex operations rapidly. The results are barbell bars boasting consistently tight tolerances, high strength, flawless appearance, and long-term functionality.

Advancing Bar Quality Through Technology

While core training principles remain unchanged, barbell bar manufacturing technology has profoundly evolved. Innovations have enabled key quality enhancements:

- Greater structural integrity from heat treating and seamless construction.

- Enhanced load capacity via optimized steel grades and tempering.

- Lighter, more rigid bars thanks to hollow engineering and tapered grips.

- Improved corrosion resistance with hard chrome plating.

- Excellent grip and hand safety from knurling techniques.

- Consistent spinning performance from precision bearings and bushings.

- Validation of key metrics like tensile strength, straightness, and hardness.

- Reduction in imperfections through automated quality control and testing.

- High-performance coatings for aesthetics and durability.

Driven by rising demand and modern manufacturing capabilities, barbell bars have evolved into specialized high-precision pieces of exercise equipment. Ongoing technology advancements will doubtlessly take future bar designs and engineering even further.

The Role of Materials in Barbell Manufacturing

The materials used in barbell manufacturing play a crucial role in determining the bar's performance and durability. High-quality steel is the most common material, known for its strength and resilience. However, advancements in material science have introduced new alloys and coatings that enhance the barbell's lifespan and performance. For example, some barbells are coated with chrome or cerakote to prevent rust and improve grip.

Modern barbells are often made from high-grade steel alloys that provide superior strength-to-weight ratios. These materials are carefully selected to ensure that the barbell can withstand heavy loads and repeated use without compromising its structural integrity. Additionally, the use of advanced coatings not only enhances the barbell's durability but also improves its aesthetic appeal, making it a popular choice among gym owners and athletes.

Customization in Barbell Manufacturing

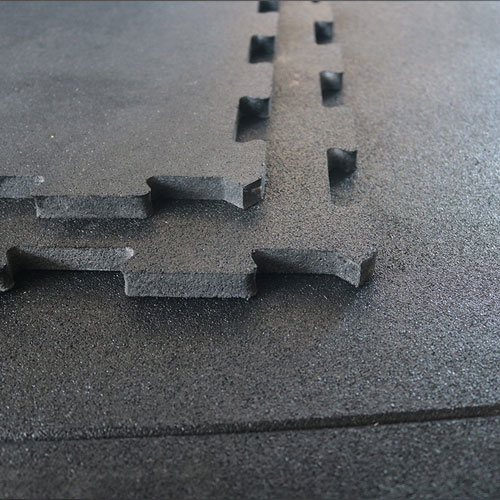

Customization is becoming increasingly important in the fitness industry. Athletes and gym owners are looking for equipment that caters to their specific needs. Leadman Fitness, with its four specialized factories—Rubber-Made Products Factory, Barbell Factory, Casting Iron Factory, and Fitness Equipment Factory—offers a wide range of customizable options. This not only ensures that customers get exactly what they need but also helps in reducing costs by streamlining the manufacturing process.

Customizable barbells can include specific knurling patterns, custom lengths, and unique coatings. These tailored solutions allow gym owners to create a unique training environment that meets the needs of their members. Additionally, customization can help in branding, as gyms can have their logos or specific colors integrated into the barbells.

The Importance of Proper Maintenance

Maintaining your barbell is essential for ensuring its longevity and performance. Regular cleaning, proper storage, and occasional lubrication of the sleeves can go a long way in keeping your barbell in top condition. Neglecting maintenance can lead to rust, reduced performance, and even safety hazards.

Regular cleaning is crucial for preventing rust and maintaining the barbell's performance. Use a mild detergent and a soft cloth to clean the bar, and avoid using harsh chemicals that could damage the coating. Proper storage is also essential for protecting your barbell from damage. Store the bar in a dry, cool place, and avoid exposing it to moisture or extreme temperatures.

Choosing the Right Barbell for Your Needs

Selecting the right barbell depends on your specific fitness goals and the type of training you engage in. Olympic barbells, powerlifting bars, and specialty bars each serve different purposes. For instance, Olympic barbells are designed for dynamic lifts like the snatch and clean & jerk, while powerlifting bars are built to handle heavy loads with minimal whip.

Specialty bars, such as trap bars and safety squat bars, offer unique benefits and can enhance your training experience. When choosing a barbell, consider factors like the type of training you do, the weight capacity you need, and the level of durability required. Leadman Fitness offers a wide range of barbells designed to meet the needs of athletes and gym owners alike.

The Future of Barbell Manufacturing

The future of barbell manufacturing looks promising, with advancements in materials, design, and customization leading the way. As fitness trends evolve, so too will the equipment we use. Leadman Fitness is at the forefront of this evolution, continuously innovating to meet the needs of modern athletes and gym owners.

Future advancements may include the use of smart technology, such as sensors integrated into barbells to provide real-time feedback on performance. Additionally, sustainability will play a key role in the future of barbell manufacturing, with eco-friendly materials and manufacturing processes becoming increasingly important.

Conclusion

The evolution of barbell manufacturing has been marked by significant advancements in technology and materials. From the rudimentary methods of ancient times to the highly automated processes of today, barbell bars have become essential tools for strength training. As the fitness industry continues to grow, so too will the innovations in barbell manufacturing, ensuring that athletes and gym owners have access to the best equipment available.

Leadman Fitness remains committed to providing high-quality, customizable barbells that meet the needs of modern fitness enthusiasts. With a focus on innovation, durability, and performance, Leadman Fitness is your trusted partner in achieving your fitness goals.

FAQ about Barbell Manufacturing

1. What materials are used in barbell manufacturing?

High-quality steel is the most common material used in barbell manufacturing. However, advancements in material science have introduced new alloys and coatings that enhance the barbell's lifespan and performance. For example, some barbells are coated with chrome or cerakote to prevent rust and improve grip.

2. How do I choose the right barbell for my needs?

Selecting the right barbell depends on your specific fitness goals and the type of training you engage in. Olympic barbells, powerlifting bars, and specialty bars each serve different purposes. For instance, Olympic barbells are designed for dynamic lifts like the snatch and clean & jerk, while powerlifting bars are built to handle heavy loads with minimal whip.

3. How can I maintain my barbell?

Maintaining your barbell is essential for ensuring its longevity and performance. Regular cleaning, proper storage, and occasional lubrication of the sleeves can go a long way in keeping your barbell in top condition. Neglecting maintenance can lead to rust, reduced performance, and even safety hazards.

4. What is the future of barbell manufacturing?

The future of barbell manufacturing looks promising, with advancements in materials, design, and customization leading the way. As fitness trends evolve, so too will the equipment we use. Leadman Fitness is at the forefront of this evolution, continuously innovating to meet the needs of modern athletes and gym owners.

5. Why is customization important in barbell manufacturing?

Customization is becoming increasingly important in the fitness industry. Athletes and gym owners are looking for equipment that caters to their specific needs. Leadman Fitness offers a wide range of customizable options to meet these demands, ensuring that customers get exactly what they need while also reducing costs by streamlining the manufacturing process.

6. What are the benefits of using high-quality barbells?

High-quality barbells offer several benefits, including greater structural integrity, enhanced load capacity, improved corrosion resistance, and excellent grip and hand safety. These features ensure that the barbell can withstand heavy loads and repeated use without compromising its performance or durability.

7. How does Leadman Fitness ensure the quality of its barbells?

Leadman Fitness ensures the quality of its barbells through comprehensive automation, advanced manufacturing technologies, and rigorous quality control processes. From raw material processing to final inspection, every step is meticulously monitored to ensure that the barbells meet the highest standards of performance and durability.

8. What are the key features to look for in a barbell?

When choosing a barbell, key features to consider include the type of training you do, the weight capacity you need, the level of durability required, and the type of coating or finish. Additionally, consider factors like knurling patterns, bar whip, and sleeve rotation, which can significantly impact your lifting experience.

9. How does Leadman Fitness support gym owners with barbell customization?

Leadman Fitness supports gym owners by offering a wide range of customizable options, including specific knurling patterns, custom lengths, and unique coatings. These tailored solutions allow gym owners to create a unique training environment that meets the needs of their members while also enhancing their brand identity