The Comprehensive Guide to Rubber Weight Plates

Introduction to Rubber Weight Plates

In the evolving world of strength training equipment, rubber weight plates have emerged as a preferred choice for both commercial gyms and home fitness enthusiasts. These versatile plates offer a unique combination of durability, safety, and performance that makes them stand out from traditional iron plates. Whether you're outfitting a high-traffic gym or building your personal home setup, understanding the benefits of rubber plates can help you make informed decisions about your strength training equipment.

Top Benefits of Rubber Weight Plates

1. Superior Floor and Equipment Protection

One of the most significant advantages of rubber plates is their ability to protect both your flooring and your barbells. The rubber coating absorbs impact when plates are dropped, which:

Prevents concrete cracking in home gyms and commercial facilities

Reduces wear and tear on Olympic platforms

Minimizes damage to barbell sleeves and collars

Preserves the integrity of gym flooring systems

This protective quality makes rubber plates particularly valuable for high-intensity training facilities where weights are frequently dropped from overhead positions.

2. Reduced Noise Levels

The noise reduction capabilities of rubber plates transform the training environment:

Creates a more pleasant workout atmosphere

Allows for early morning/late night training without disturbing others

Reduces noise complaints in multi-unit buildings

Enables clearer communication between trainers and clients

3. Enhanced Safety Features

Rubber plates offer several safety advantages that make them ideal for various training environments:

Non-slip surface: The rubber coating provides better grip when loading/unloading bars

Reduced bounce: Compared to bumper plates, rubber-coated iron plates have minimal rebound

Protective edges: Rounded rubber edges prevent cuts and scrapes during handling

Stable storage: Rubber surfaces prevent plates from sliding when stacked

4. Long-Term Durability and Weather Resistance

The construction of quality rubber plates ensures exceptional longevity:

Rust prevention: The rubber coating protects the iron core from moisture and oxidation

UV resistance: High-quality rubber compounds withstand sunlight exposure

Temperature tolerance: Performs well in both hot and cold environments

Wear resistance: Durable rubber maintains its properties through years of use

Practical Applications of Rubber Plates

1. Commercial Gym Settings

Rubber plates are particularly well-suited for high-traffic fitness facilities because:

They withstand constant use and abuse from multiple users daily

The noise reduction creates a better member experience

They maintain a professional appearance over time

Reduced maintenance requirements lower long-term costs

2. Home Gym Solutions

For home fitness enthusiasts, rubber plates offer unique advantages:

Space-efficient design allows for compact storage

Quieter operation maintains household harmony

Multi-surface compatibility (can be used on concrete, rubber flooring, etc.)

Safer for families with children or pets

3. Specialized Training Facilities

Certain training environments particularly benefit from rubber plates:

Sports performance centers: Where explosive movements are common

Rehabilitation clinics: Where safety and noise control are priorities

School/University gyms: Where equipment sees varied use

Technical Specifications and Variations

1. Construction and Materials

Quality rubber plates feature:

High-density rubber coating: Typically 10-20mm thick for optimal protection

Precision-cast iron core: For accurate weight distribution

Reinforced center holes: With steel inserts to prevent wear

Color-coded designs: For easy weight identification

2. Weight Increments and Sizes

Rubber plates are available in a comprehensive range:

Standard increments: From 1.25kg microplates to 25kg+ plates

Diameter variations: Olympic (50mm) and standard (25mm) hole sizes

Thickness options: Slim-profile designs for higher weight capacity on bars

Full sets: Typically ranging from 50kg to 300kg total weight

FAQ About Rubber Weight Plates

How do rubber plates compare to bumper plates?

While both have rubber exteriors, bumper plates are 100% rubber for Olympic lifting, while rubber plates have an iron core with rubber coating. Bumpers are designed to be dropped from overhead, while rubber plates offer more weight options in compact sizes.

Are rubber plates more expensive than iron plates?

Rubber plates typically cost 20-40% more than basic iron plates, but the investment pays off in longevity, safety, and facility protection. For high-use environments, they often prove more cost-effective long-term.

Can rubber plates be used outdoors?

Yes, quality rubber plates are weather-resistant and can be used outdoors, though we recommend storing them indoors when not in use to maximize their lifespan.

Ready to Upgrade to High-Quality Rubber Weight Plates?

Our premium rubber weight plates combine durability, performance, and safety in a range of sizes to meet your strength training needs.

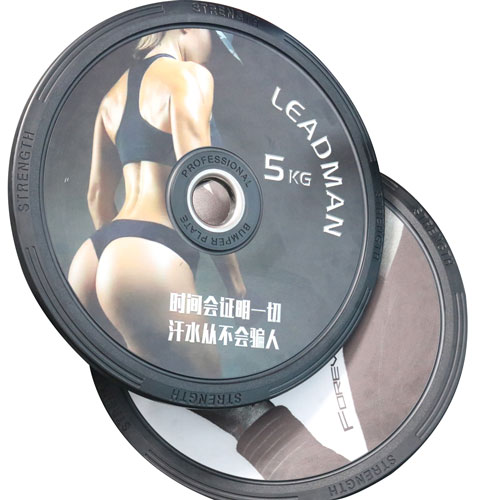

Leadman Fitness offers commercial-grade rubber plates with customizable options. Contact our team today for specifications and pricing!

Making the Right Choice for Your Needs

When selecting rubber weight plates, consider these factors:

Usage frequency: Commercial facilities need heavier-duty options

Space constraints: Slimmer profiles maximize bar capacity

Training style: Powerlifters vs. general fitness vs. functional training

Budget considerations: Balance initial cost with long-term value

Aesthetic preferences: Color options and branding opportunities

By understanding the comprehensive benefits and applications of rubber weight plates, you can make an informed decision that enhances your training experience while protecting your investment in fitness equipment.